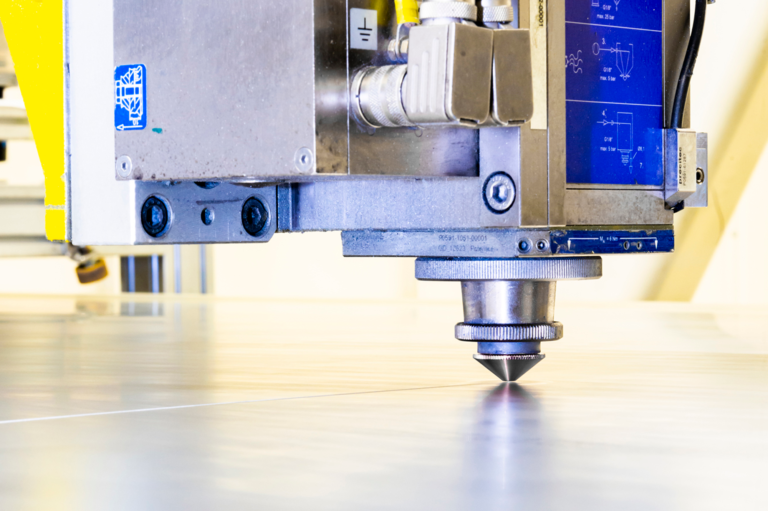

High-tech and flexibility are at the center of our laser blanking line. Our newly built production hall is in constant overpressure, creating a dust-free environment. The aluminium or (stainless) steel material flows continuously from the coil into the laser cell. This cell consists of two laser portals in which three lasers can move independently of each other. The optimal nesting of the blanks allows us to produce significantly more parts per coil (up to 30%).

New blank shapes can be programmed or adjusted easily. The laser blanking makes the blank edges homogeneous. The line is fully equipped with a surface inspection system. At the end of the process, a robot accurately stacks the parts before they are wrapped in foil. Pallets are stored optimal conditions in our airconditionned hall.

Discover

our laser blanking line

Technical details

| Aluminium | (Stainless) Steel | |

|---|---|---|

| Coil width | 400 – 2.150mm | 400 – 2.150mm |

| Inner diameter | 508 – 610mm | 508 – 610mm |

| Outer diameter | 2.200mm | 2.200mm |

| Max. coil weight | 15t | 15t |

| Thickness | 0,7 - 3,2mm | 0,5 - 1,5mm |

| Length of sheet | 300 – 4.000 mm | 300 – 4.000 mm |

| Max. sheet weight | 300kg | 300kg |

Download technical data